Биореактор с подвижной кроватью (MBBR)Умная конструкция MBBR обеспечивает наименьшую общую стоимость владения в течение всего срока службы установки.Зачем тратить деньги на строительство завода?, и когда вы используете и обслуживаете его?Умный дизайн MBBR часто обеспечивает наименьшую общую стоимость владения и наиболее легкую эксплуатацию.

Принцип процесса MBBR основан на фундаментальных понятиях технологии биофильмов,когда в реактор добавляется определенное количество суспензионных носителей для увеличения биомассы и микробиологического разнообразия в системеПоскольку плотность носителей близка к плотности воды, они полностью смешиваются с водой во время проветривания.создание среды роста микробов, включающей газ, жидкие и твердые фазы.

В результате столкновения и сдвига носителей в воде пузыри распадаются на меньшие размеры, что повышает эффективность использования кислорода.на внутренней и внешней поверхности каждого носителя растут различные виды микроорганизмовАнаэробные или факультативные бактерии процветают внутри носителей, в то время как аэробные бактерии колонизируют внешние поверхности.позволяющий одновременное нитрирование и денитрирование, тем самым повышая общую эффективность лечения.

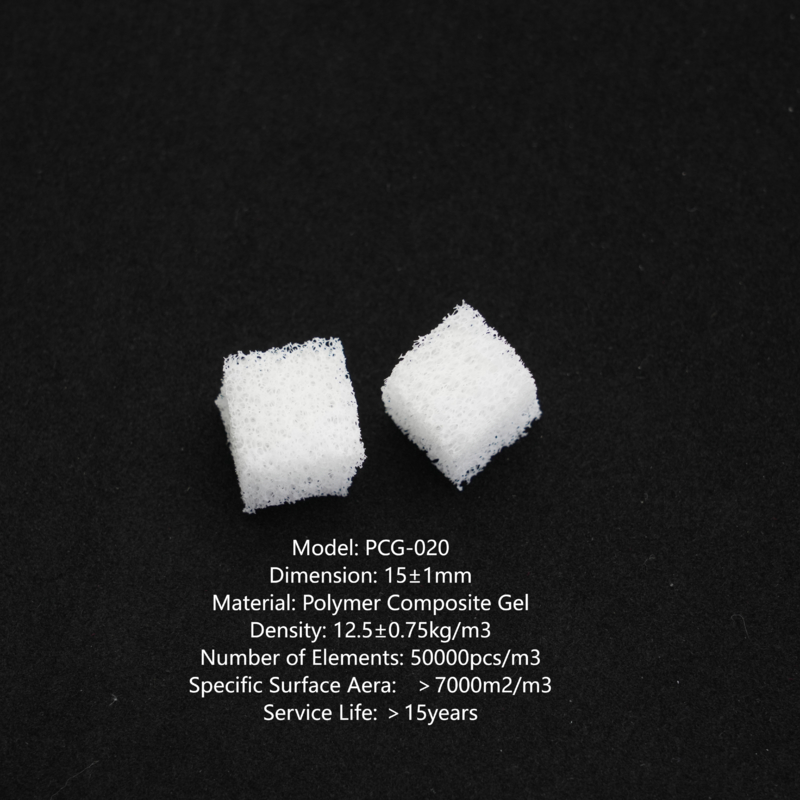

Технические параметры:

| Наименование продукта |

MBBR в очистке сточных вод |

| Материал |

HDPE (полиэтилен высокой плотности) |

| Эффективная поверхность |

> 500 м2/м3 |

| Соотношение пустоты |

> 95% |

| Специфическая гравитация |

> 0,96 г/см3 |

| Диапазон pH |

5-15 |

| Время подвешивания мембраны |

5-15 дней |

| Заявления |

Промышленная, муниципальная и бытовая очистка сточных вод |

| Ключевые особенности |

Интегрированная биофильм-реактор-система, микробиологическая биофильм-реактор-система, биофильм-носитель-обработка-система |

Преимущества метода MBBR

MBBR, который обычно известен как двигательный биофильмный реактор, является современной технологией и процессом очистки воды.Он был впервые изобретен в конце 1980-х годов профессором Холлвардом из Норвежского университета науки и технологии..

В отличие от большинства традиционных систем очистки воды,MBBR - это высокоэффективный биологический процесс очистки воды, основанный на сочетании биофильмовой среды и обычных процессов очистки активных ила.Таким образом, вода может быть обработана как в анаэробной, так и в аэробной среде.

MBBR в настоящее время является лучшим решением для обработки воды для высокопрочных систем водоснабжения.которая использует системы MBBR, тем самым улучшая качество отходов и увеличивая емкость обработки без увеличения дополнительного объемаИ вы можете использоватьСредства K1и MBBR для улучшения качества воды в системах MBBR.

Часто задаваемые вопросы (FAQ)

Вопрос 1: Каков срок службы OEM MBBR BioMedia?

О: Наши носители HDPE MBBR прослужат более 10 лет из-за превосходной прочности материала.

Вопрос 2: Может ли эта среда использоваться в анаэробных реакторах?

О: Да, он поддерживает как аэробные, так и анаэробные биофильмы для полной очистки сточных вод.

Вопрос 3: Как MBBR улучшает удаление азота?

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!