Two Stage Type Rotary Drum Thickening/Dehydrating Belt Filter Press for Industrial -DTB Series

Industrial Belt Filter Press Solid Liquid Separation Processes-Standard Type

DESCRIPTION

DESCRIPTION

The belt filter press (sometimes called a belt press filter, or belt filter) is an industrial machine used for solid-liquid separation processes.

A belt filter press is a type of industrial filtration equipment used to separate liquids and solids from a slurry mixture. The press consists of a series of belts that are arranged in a loop and used to filter the slurry as it passes through the press.

APPLICATION

APPLICATION

1. The sludge dewatering of the various industrial wastewater treatment plants.

2. The sludge dewatering of the butchery, livestock, etc.

3. The sludge dewatering of the city sewer, excretion, water purifying, etc. Sewage treatment plants.

4. Solid and liquid separate under processing for the food & beverage, chemical industry, mine, etc.

FEATURES

FEATURES

High-efficiency of products dehydration, a large quantity of sludge treatment, automatic operation, low power consumption, low noise, simple structure, semi-enclosed structure, easy maintenance; this machine is simple, easy to understand, easy to learn, the common operators could run the whole process after a short period of time training.

BENEFITS

BENEFITS

Continuous auto running;

Low power consumption, the longevity of service;

Easy to manage, easy to maintain;

Low noise, low consumption of PAM dosage ;

Economical, reliable, and wide application.

Belt Position Correcting System

Belt Position Correcting System

This system can automatically keep detecting and rectifying the deviation of belt cloth, so as to guarantee the normal operation of our machine and also extend the lifespan of the belt.

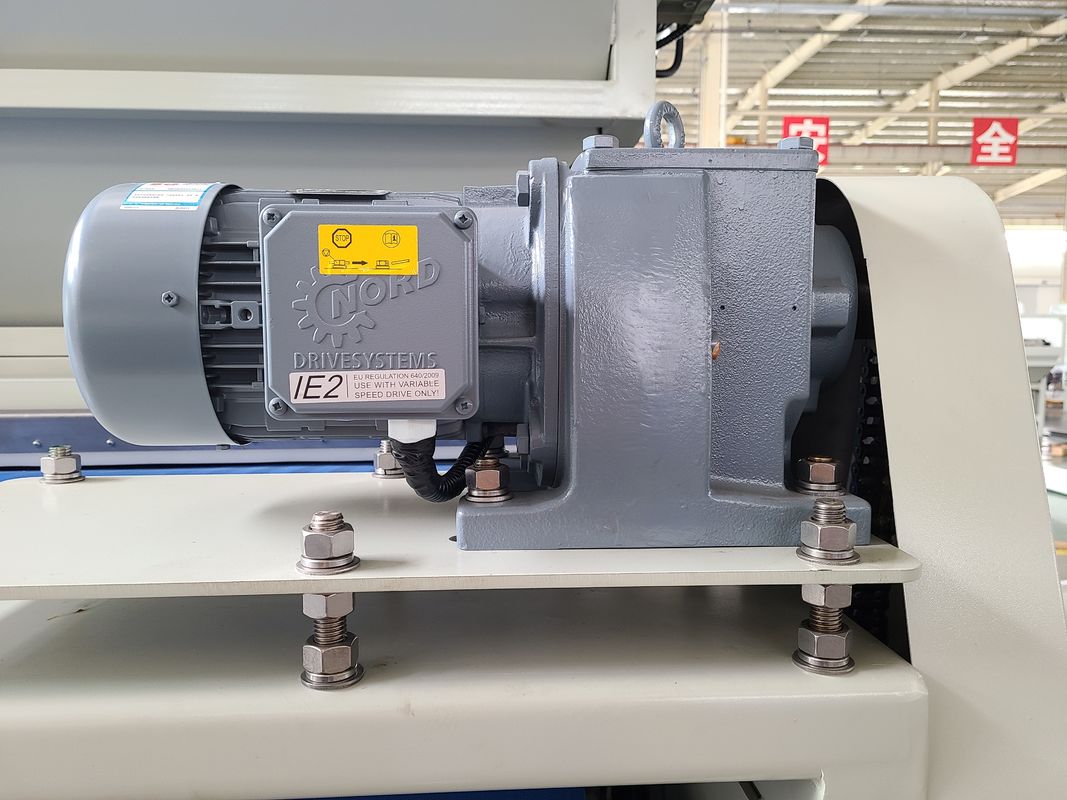

■Press Roller

The press roller of our sludge belt filter press is made from SUS304 stainless steel. Additionally, it has gone through the TIG reinforced welding process and exemplary finishing process, thus featuring a compact structure and ultra-high strength.

■Air Pressure Control Device

Tensioned by an air cylinder, the filter cloth can run smoothly and safely without any leakage.

How Our Belt Filter Press Works

How Our Belt Filter Press Works

- After flocculation and compression periods, the slurry is delivered to a porous belt for thickening and gravity dewatering.

- A large amount of free water is separated by gravity, and then the slurry solids are formed.

- After that, the slurry is sandwiched between two tensioned belts to pass through the wedge-shaped pre-compression zone, low-pressure zone, and high-pressure zone.

- It is extruded step by step to maximize the separation of sludge and water.

- At last, the filter cake is formed and discharged.

Technical Data & External Dimensions of Belt Filter Press

Technical Data & External Dimensions of Belt Filter Press

Remark:

1. Our company will reserve the modifying right of the above specifications.

2. Treating capacity and the water content rate depend on the slurry feature

3. Please ask for the actual installation dimension before ordering.

Allocation Schema for Peripheral Equipment

Allocation Schema for Peripheral Equipment

The Reference Treating Data Sheet of The Major Waste Slurry

The Reference Treating Data Sheet of The Major Waste Slurry

Welcome To DUBHE

Welcome To DUBHE

Q1: How to pay?

A: 100%T/T, Paypal, West Union, MoneyGram, Secure payment and Trade Assurance.

Q2: What's the delivery time?

A: 30-60 days.

Q3: What's the MOQ?

A: The MOQ is one set.

Q4: Do you have an inspection report for the material?

A: We can provide you with the relative certificates.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!