Projekt MBBR obejmuje wiele komponentów, które współdziałają w celu zwiększenia wydajności technologii. Po pierwsze, proces odbywa się w zbiorniku napowietrzania (lub basenie napowietrzania). Ogólne wymiary zbiornika napowietrzania zależą od rodzaju i objętości ścieków, które mają być oczyszczane. Dopływ wpływa do zbiornika napowietrzania na początku procesu oczyszczania. Drugim komponentem jest nośnik, który składa się z wspomnianych swobodnie pływających bionośników, które mogą zajmować do 70% objętości zbiornika napowietrzania. Po trzecie, kratka napowietrzająca odpowiada za ułatwianie ruchu nośnika w zbiorniku napowietrzania, zapewniając maksymalny kontakt między nośnikami a ściekami, jednocześnie dostarczając tlen do zbiornika. Wreszcie, sito zatrzymuje wszystkie nośniki w zbiorniku napowietrzania, zapobiegając wydostawaniu się plastikowych nośników podczas procesu napowietrzania.

Chociaż istnieje kilka różnych metod operacyjnych, wszystkie wykorzystują te same komponenty konstrukcyjne. Metoda przepływu ciągłego obejmuje ciągły dopływ ścieków do zbiornika, podczas gdy oczyszczona woda jest odprowadzana przez sito z równoważnym natężeniem przepływu. Metoda napowietrzania przerywanego działa z naprzemiennymi cyklami napowietrzania i nienapowietrzania, umożliwiając warunki zarówno tlenowe, jak i anoksyczne. Metoda reaktora wsadowego sekwencyjnego (SBR) jest przeprowadzana w pojedynczym reaktorze, gdzie wiele etapów oczyszczania jest wykonywanych sekwencyjnie, a oczyszczona woda jest usuwana przed ponownym rozpoczęciem cyklu. Miksery zanurzeniowe o dużej średnicy są powszechnie stosowane jako metoda mieszania w tych systemach.

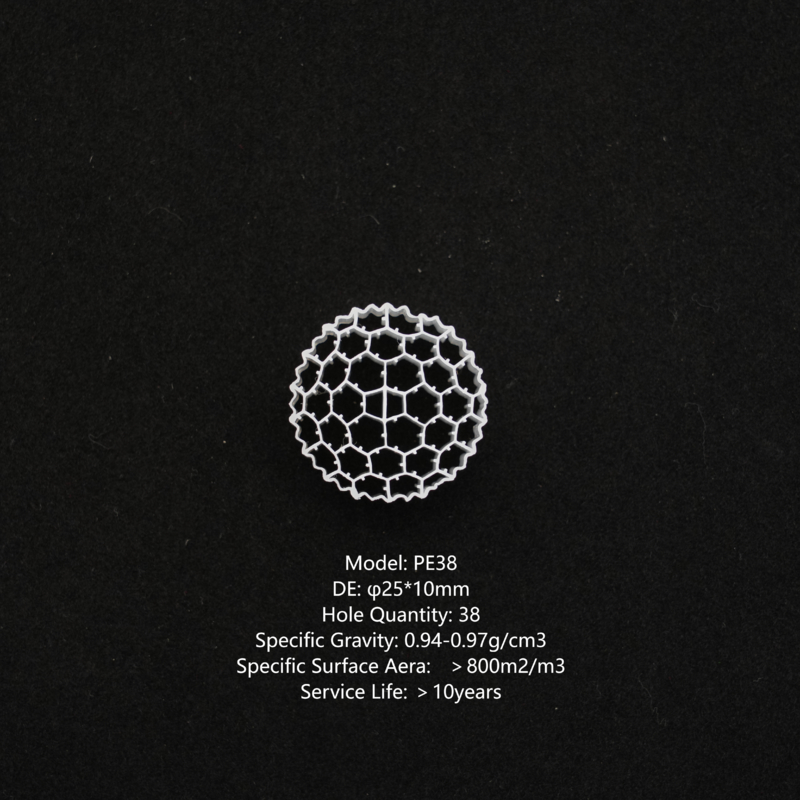

Parametry techniczne:

| Nazwa produktu |

MBBR w oczyszczaniu ścieków |

| Materiał |

HDPE (polietylen o dużej gęstości) |

| Wydajna powierzchnia |

>500 ㎡/m³ |

| Współczynnik pustki |

>95% |

| Ciężar właściwy |

>0,96 g/cm³ |

| Zakres pH |

5-15 |

| Czas zawieszania membrany |

5-15 dni |

| Zastosowania |

Przemysłowe, komunalne, oczyszczanie ścieków domowych |

| Kluczowe cechy |

Zintegrowany system reaktora biofilmu, system reaktora biofilmu mikrobiologicznego, system oczyszczania nośnika biofilmu |

Jak działa mbbr

W przeciwieństwie do procesu polerowania, MBR jest używany jako trzeci etap oczyszczania wody, który nie ma powrotu aktywnej biomasy do procesu biologicznego. Obecnie większość procesów MBR w miejscach komercyjnych wykorzystuje membranę jako filtr, który odrzuca wszystkie stałe materiały powstałe w procesie naturalnym.

Pomaga to w uzyskaniu zdezynfekowanego i oczyszczonego produktu ściekowego.

Często zadawane pytania (FAQ)

P1: Jaka jest żywotność OEM MBBR BioMedia?

O: Nasze nośniki HDPE MBBR wytrzymują ponad 10 lat dzięki doskonałej trwałości materiału.

P2: Czy ten nośnik może być używany w reaktorach beztlenowych?

O: Tak, obsługuje zarówno tlenowe, jak i beztlenowe procesy biofilmu dla pełnego oczyszczania ścieków.

P3: Jak MBBR poprawia usuwanie azotu?

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!