Optimized Product Description:

MBBR bio-media, also known as fluidized bed media, is used in the aerobic biological fluidized bed process. The MBBR media features a three-dimensional hollow structure that serves as a carrier for aerobic microorganisms. During normal operation, the media remains suspended in the water. It offers advantages such as high resistance to shock loads, efficient treatment performance, long sludge age, reduced excess sludge production, effective nitrogen and phosphorus removal, and no sludge bulking issues.

The core principle of MBBR involves utilizing suspended bio-media (typically made of plastic) in the reactor, which provides a surface for microorganisms to attach and form biofilms. The treatment process consists of the following steps:

Wastewater enters the reactor: Wastewater flows into the reactor containing the bio-media, where the media move freely under the action of water flow and aeration.

Biodegradation: Microorganisms form biofilms on the surface of the media, adsorbing and breaking down organic pollutants and ammonia nitrogen in the wastewater.

Aeration: An aeration system supplies oxygen to promote the growth of aerobic microorganisms and the degradation of organic matter.

Solid-liquid separation: This is typically carried out in a subsequent sedimentation tank or filtration system, where the bio-media are separated from the treated clear water.

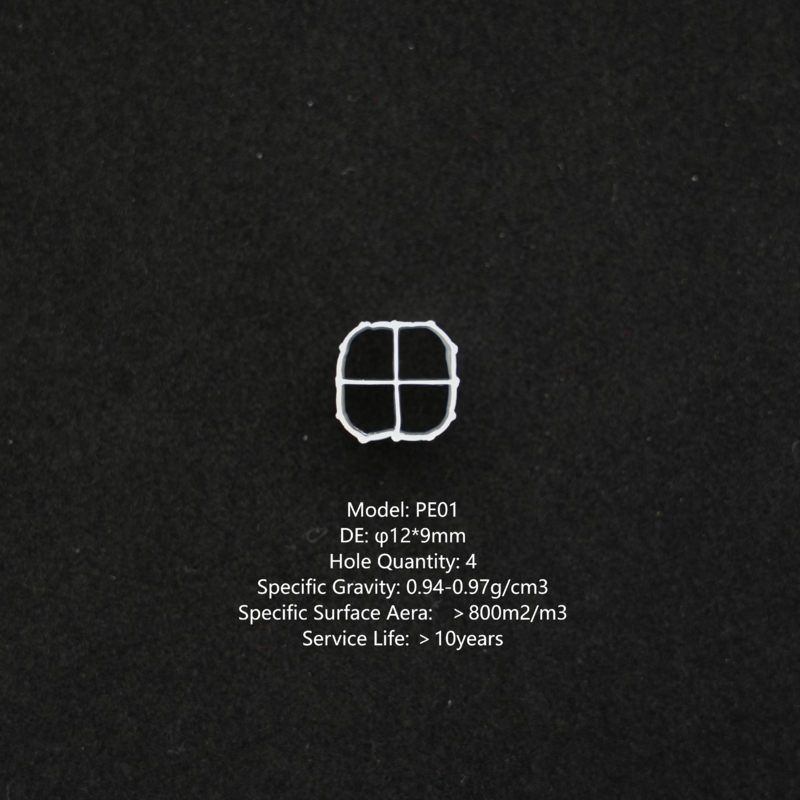

Technical Parameters:

| Product Name |

MBBR In Wastewater Treatment |

| Material |

HDPE (High-Density Polyethylene) |

| Efficient Surface |

>500 ㎡/m³ |

| Void Ratio |

>95% |

| Specific Gravity |

>0.96 g/cm³ |

| pH Range |

5-15 |

| Membrane Hanging Time |

5-15 days |

| Applications |

Industrial, Municipal, Domestic Wastewater Treatment |

| Key Features |

Integrated-Biofilm-Reactor-System, Microbial-Biofilm-Reactor-System, Biofilm-Carrier-Treatment-System |

Applications of MBBR

Municipal Wastewater Treatment

MBBR systems are widely used in municipal wastewater treatment plants, effectively treating domestic sewage, improving effluent quality, and reducing pollutant discharge.

Industrial Wastewater Treatment

MBBR technology is suitable for treating various types of industrial wastewater, such as from the food processing, pharmaceutical, petrochemical, and papermaking industries. It can handle high-concentration organic wastewater and toxic substances.

Water Reclamation Systems

In water reclamation systems, MBBR technology can be applied to wastewater reuse systems in office buildings, residential communities, and industrial parks, enabling the recycling of water resources.

Sludge Reduction

MBBR technology offers advantages in sludge reduction treatment, effectively lowering sludge production and reducing the cost of sludge handling and disposal.

High-Concentration Organic Wastewater Treatment

MBBR systems are suitable for treating high-concentration organic wastewater, such as restaurant wastewater and slaughterhouse wastewater. Treatment efficiency is enhanced by increasing the quantity of bio-media.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of OEM MBBR BioMedia?

A: Our HDPE MBBR carriers last 10+ years due to superior material durability.

Q2: Can this media be used in anaerobic reactors?

A: Yes, it supports both aerobic & anaerobic biofilm processes for complete wastewater treatment.

Q3: How does MBBR improve nitrogen removal?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!