Due to issues such as hydraulic instability and uneven biofilm distribution in early-stage biofilm reactors, Moving Bed Biofilm Reactor (MBBR) technology was developed. An MBBR system consists of an aeration tank (similar to an activated sludge tank) and specialized plastic carriers that provide surfaces for biofilm growth. The plastic carriers used in these systems vary widely in type, with differences in surface area and shape, each having its own advantages and disadvantages. Surface area plays a critical role in biofilm formation. The free-floating carriers allow biofilm to develop on their surfaces; thus, a larger internal surface area is essential for effective contact with water, air, bacteria, and nutrients. The aeration system mixes the carriers within the tank, ensuring optimal contact between the substrates in the influent and the biomass attached to the carriers. Currently, the most preferred material is high-density polyethylene (HDPE), due to its moldability, density, and durability. [Citation needed]

To achieve higher biomass concentrations in bioreactors, hybrid MBBR systems have been adopted, where suspended biomass and attached biomass coexist and jointly participate in the biological processes. Additionally, anaerobic MBBR is primarily used for industrial wastewater treatment. A 2019 article introduced a combination of anaerobic (methanogenic) MBBR and aerobic MBBR, applied in a municipal wastewater treatment laboratory setting, which simultaneously produced biogas.

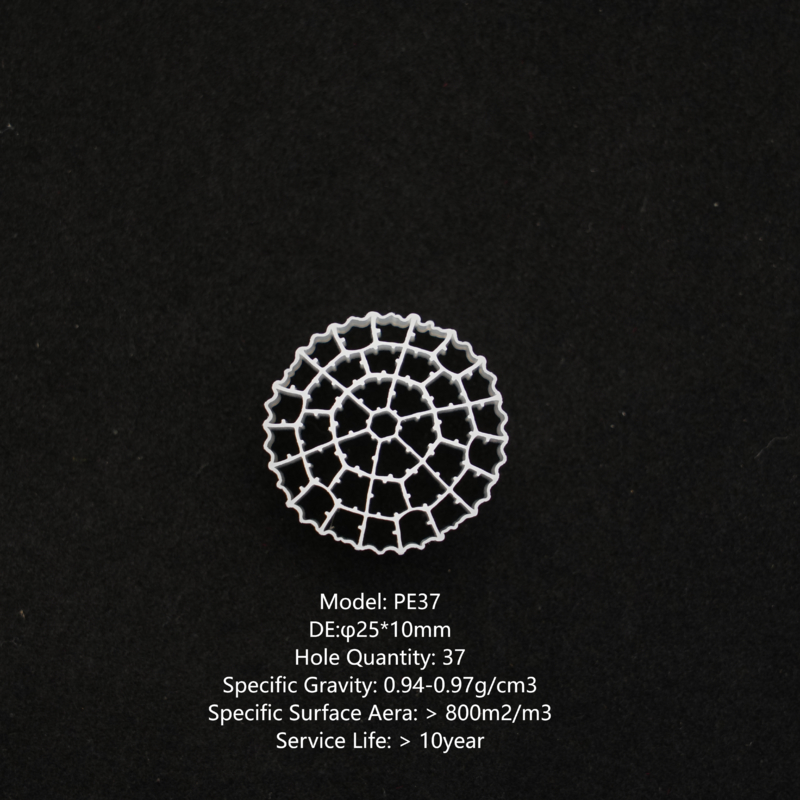

Technical Parameters:

| Product Name |

MBBR In Wastewater Treatment |

| Material |

HDPE (High-Density Polyethylene) |

| Efficient Surface |

>500 ㎡/m³ |

| Void Ratio |

>95% |

| Specific Gravity |

>0.96 g/cm³ |

| pH Range |

5-15 |

| Membrane Hanging Time |

5-15 days |

| Applications |

Industrial, Municipal, Domestic Wastewater Treatment |

| Key Features |

Integrated-Biofilm-Reactor-System, Microbial-Biofilm-Reactor-System, Biofilm-Carrier-Treatment-System |

Advantages of the MBBR Process

1. High Volumetric Loading, Compact and Space-Saving

Particularly effective for upgrading existing wastewater treatment plants, it significantly increases treatment capacity by 2-3 times without requiring additional land, while also improving effluent quality through simple modifications to existing infrastructure.

2. Strong Shock Load Resistance, Stable Performance, Reliable Operation

The impact of shock loads and temperature fluctuations on the MBBR process is far less severe than on activated sludge systems. Biofilms demonstrate high tolerance to changes in wastewater composition and increased toxicity.

3. Easy Operation and Maintenance of Aeration and Mixing Systems

The aeration system uses perforated pipes that are resistant to clogging. Agitators equipped with banana-shaped mixing blades feature smooth contours that do not damage the carriers. The entire aeration and mixing system is simple to maintain and manage.

4. No Clogging in the Biological Tank, Full Utilization of Tank Volume, No Dead Zones

As the carriers and water flow are thoroughly mixed throughout the entire biological tank, the risk of clogging is eliminated, ensuring complete utilization of the tank volume.

5. Flexibility and Convenience

The process offers flexibility in two key aspects. Firstly, it can be applied to various tank configurations (deep, shallow, square, or round) without compromising treatment efficiency. Secondly, different carrier filling ratios can be flexibly selected to balance high efficiency with future capacity expansion needs without increasing tank volume. For retrofitting and upgrading existing activated sludge plants, the MBBR process can be seamlessly integrated to form hybrid activated sludge-biofilm systems or fluidized bed activated sludge combined processes.

6. Long Service Life

The use of high-quality, durable bio-carriers, aeration systems, and effluent devices ensures long-term operation without the need for replacement, resulting in low depreciation rates.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of OEM MBBR BioMedia?

A: Our HDPE MBBR carriers last 10+ years due to superior material durability.

Q2: Can this media be used in anaerobic reactors?

A: Yes, it supports both aerobic & anaerobic biofilm processes for complete wastewater treatment.

Q3: How does MBBR improve nitrogen removal?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!