Optimized Product Description:

The Moving Bed Biofilm Reactor (MBBR) is an efficient biological wastewater treatment process. This technology combines the characteristics of both the activated sludge process and the biological contact oxidation method, utilizing suspended carriers to achieve full contact with wastewater for pollutant removal. The MBBR process demonstrates strong resistance to shock loads and stable operational performance, making it suitable for upgrading various systems such as A2O, oxidation ditches, SBR, and AB processes. Compared to fixed-bed biofilm processes, the MBBR process significantly increases volumetric loading capacity without imposing specific requirements on influent SS or organic loading. Additionally, it effectively addresses issues such as excessive biofilm thickness and weight in fixed-bed systems, as well as the collapse of suspended carrier supports.

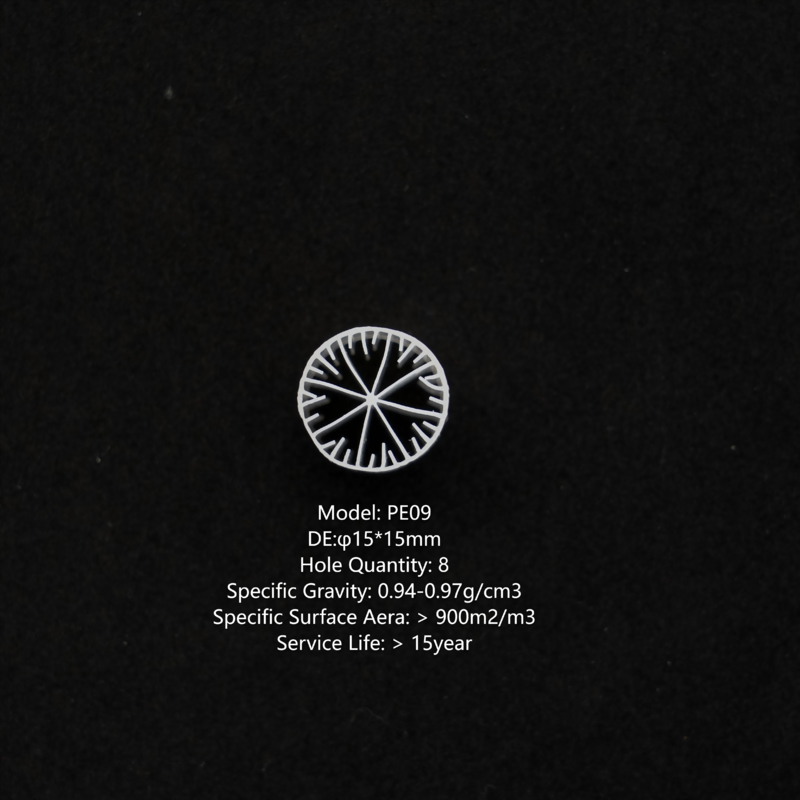

Currently, most MBBR bio-carriers are primarily made of materials such as polyethylene (PE), polypropylene (PP), polyurethane (PU), and porous polyurethane (PPC). Among these, PE-based MBBR carriers demonstrate effective removal of pollutants such as chromaticity, CODCr, ammonia nitrogen, total nitrogen, total organic carbon, and volatile phenols from wastewater. PP carriers are commonly used in combined MBBR processes, such as MBBR-AO integrated systems and MBBR-MBR hybrid technologies. PU and PPC carriers, with their high porosity, provide a larger surface area for microbial attachment, enabling rapid and stable microbial growth, thereby effectively removing organic pollutants and various nutrients from wastewater.

Technical Parameters:

| Product Name |

MBBR In Wastewater Treatment |

| Material |

HDPE (High-Density Polyethylene) |

| Efficient Surface |

>500 ㎡/m³ |

| Void Ratio |

>95% |

| Specific Gravity |

>0.96 g/cm³ |

| pH Range |

5-15 |

| Membrane Hanging Time |

5-15 days |

| Applications |

Industrial, Municipal, Domestic Wastewater Treatment |

| Key Features |

Integrated-Biofilm-Reactor-System, Microbial-Biofilm-Reactor-System, Biofilm-Carrier-Treatment-System |

Applications of MBBR

Municipal Wastewater Treatment

MBBR systems are widely used in municipal wastewater treatment plants, effectively treating domestic sewage, improving effluent quality, and reducing pollutant discharge.

Industrial Wastewater Treatment

MBBR technology is suitable for treating various types of industrial wastewater, such as from the food processing, pharmaceutical, petrochemical, and papermaking industries. It can handle high-concentration organic wastewater and toxic substances.

Water Reclamation Systems

In water reclamation systems, MBBR technology can be applied to wastewater reuse systems in office buildings, residential communities, and industrial parks, enabling the recycling of water resources.

Sludge Reduction

MBBR technology offers advantages in sludge reduction treatment, effectively lowering sludge production and reducing the cost of sludge handling and disposal.

High-Concentration Organic Wastewater Treatment

MBBR systems are suitable for treating high-concentration organic wastewater, such as restaurant wastewater and slaughterhouse wastewater. Treatment efficiency is enhanced by increasing the quantity of bio-media.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of OEM MBBR BioMedia?

A: Our HDPE MBBR carriers last 10+ years due to superior material durability.

Q2: Can this media be used in anaerobic reactors?

A: Yes, it supports both aerobic & anaerobic biofilm processes for complete wastewater treatment.

Q3: How does MBBR improve nitrogen removal?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!