The Moving Bed Biofilm Reactor (MBBR) process applies the fundamental principles of biofilm technology while fully leveraging the advantages of the activated sludge process and overcoming the limitations of both conventional activated sludge systems and fixed-bed biofilm methods. A key innovation lies in the development of bio-carriers with a specific gravity close to water, which move freely with minimal agitation. These carriers offer a large effective surface area ideal for microbial colonization.

The MBBR process is highly adaptable and applicable across a broad spectrum. It can be used for organic matter removal as well as nitrogen and phosphorus elimination. It is suitable for new wastewater treatment plants and is particularly effective for retrofitting and upgrading existing facilities.

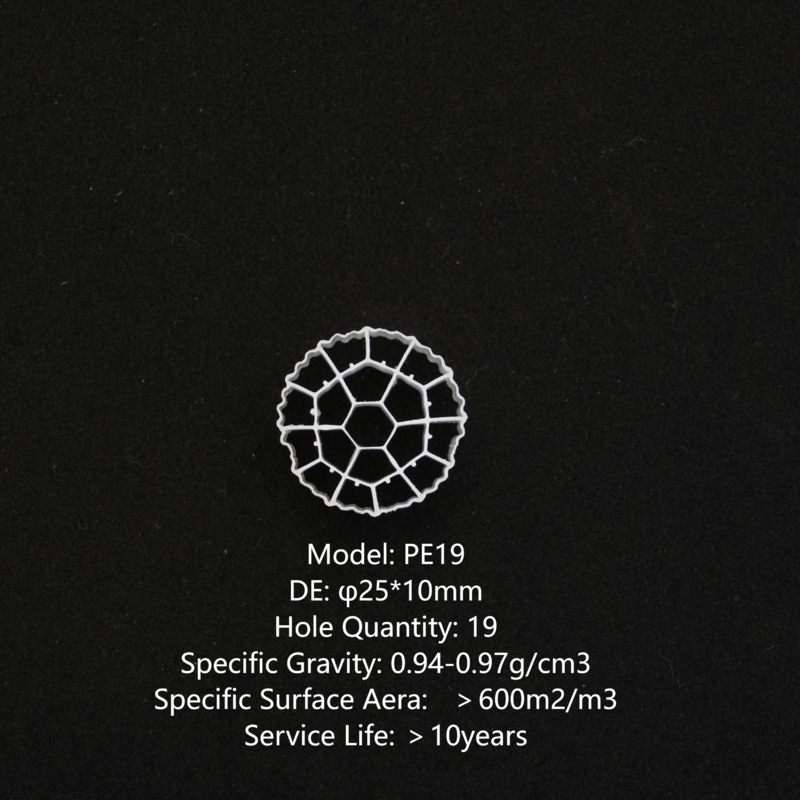

Technical Parameters:

| Product Name |

MBBR In Wastewater Treatment |

| Material |

HDPE (High-Density Polyethylene) |

| Efficient Surface |

>500 ㎡/m³ |

| Void Ratio |

>95% |

| Specific Gravity |

>0.96 g/cm³ |

| pH Range |

5-15 |

| Membrane Hanging Time |

5-15 days |

| Applications |

Industrial, Municipal, Domestic Wastewater Treatment |

| Key Features |

Integrated-Biofilm-Reactor-System, Microbial-Biofilm-Reactor-System, Biofilm-Carrier-Treatment-System |

Advantages of the MBBR Process

After successfully installing the MBBR system, you need to understand its working principle for you to get the best out of it. Luckily, the MBBR system has a simple working principle that anyone can easily understand.

For one the MBBR system has activated sludge aeration systems in which case the sludge is collected on the recycled plastic carriers. These carriers named K1 media have a large surface for air, bacteria and contact water.

The activated sludge, which is also the bacteria grows on the internal surface of the carriers. This way, organic matter from the wastewater is broken down by the bacteria.

The excess sludge with then come separate from the carriers and will then flow with the treated water towards the final separator.

This will also help eliminate the extra amount of bacteria growth.

Additionally, depending on the specific demands, the system can have one stage or more stage system. The primary bacteria of the process remain in their own duty tank since the carriers remain only in one tank.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of OEM MBBR BioMedia?

A: Our HDPE MBBR carriers last 10+ years due to superior material durability.

Q2: Can this media be used in anaerobic reactors?

A: Yes, it supports both aerobic & anaerobic biofilm processes for complete wastewater treatment.

Q3: How does MBBR improve nitrogen removal?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!